Equipment Failures: Causes, Consequences, and the Importance of Failure Analysis

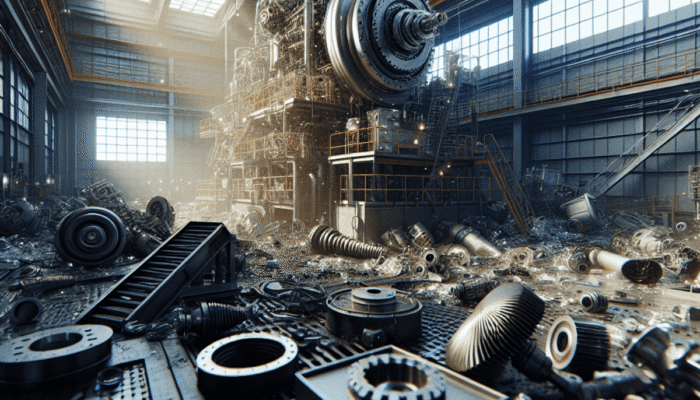

Unintended and unforeseen equipment failures can range from minor operational disruptions to serious incidents that pose risks to property, productivity, and human life. Equipment failure occurs when a component or system loses its intended functional performance, either partially or completely, resulting in operation outside of design expectations.

Equipment failures can arise from a variety of causes. Manufacturing defects may introduce hidden weaknesses that lead to premature failure. Improper design or construction can create stress concentrations, incompatible materials, or inadequate safety margins. Over time, age-related deterioration, environmental exposure, and normal wear can further degrade performance. In many cases, failures are also linked to insufficient maintenance or excessive or improper use beyond the equipment’s intended operating conditions.

When equipment fails, the consequences often extend far beyond the failed component itself. Physical damage to surrounding systems, production downtime, loss of revenue, and increased repair or replacement costs are common outcomes. In more severe cases, equipment failures can negatively impact health and safety, creating hazardous conditions for occupants or operators. These outcomes frequently trigger insurance claims, legal disputes, or warranty investigations.

At this stage, identifying responsibility becomes critical. Determining liability requires a clear understanding of what caused the failure and whether it resulted from design deficiencies, manufacturing errors, maintenance issues, misuse, or external influences. To support fair and defensible conclusions, the root cause of an equipment failure must be established within a reasonable degree of engineering certainty.

Effective equipment failure analysis goes beyond identifying what failed — it examines why it failed. In addition to determining the root cause, alternative contributing factors must be considered and ruled out. This comprehensive approach ensures that conclusions are accurate and not based on assumptions or incomplete information.

The failure analysis process typically begins with a detailed visual inspection of the equipment and the surrounding area where the failure occurred. This step allows site conditions, operating environment, and damage patterns to be evaluated. From there, further analytical procedures are conducted in a systematic manner. These may include dimensional measurements, material testing, diagnostic evaluations, and microscopic examination using specialized equipment such as high-powered microscopes.

Advanced diagnostic techniques may also be employed to analyze fracture surfaces, wear patterns, electrical components, or thermal damage. Each step in the analysis builds upon the previous findings, allowing investigators to reconstruct the sequence of events that led to the failure.

Equipment failures demand careful, methodical evaluation to ensure accurate conclusions. A thorough failure analysis provides clarity, supports informed decision-making, and helps resolve disputes related to responsibility and compensation. By understanding the causes and consequences of equipment failures, stakeholders can take steps to reduce future risks and improve system reliability.